FAA-EASA workshop

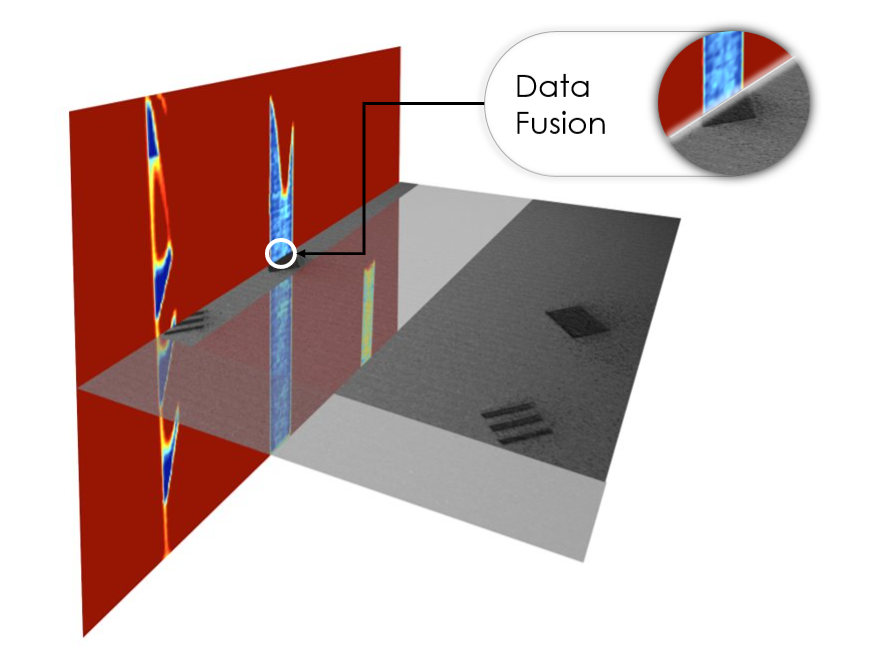

Last week, I had the chance to participate to the on-invitation EASA-FAA workshop, gathering regulatory authorities and the industry to exchange about additive manufacturing. My personal take away from the excellent meeting about in-situ monitoring: 🥉 Impressive how the industry is now able to deliver critical parts for aviation using metal additive manufacturing ! 🎯 Cost reduction…

Read more