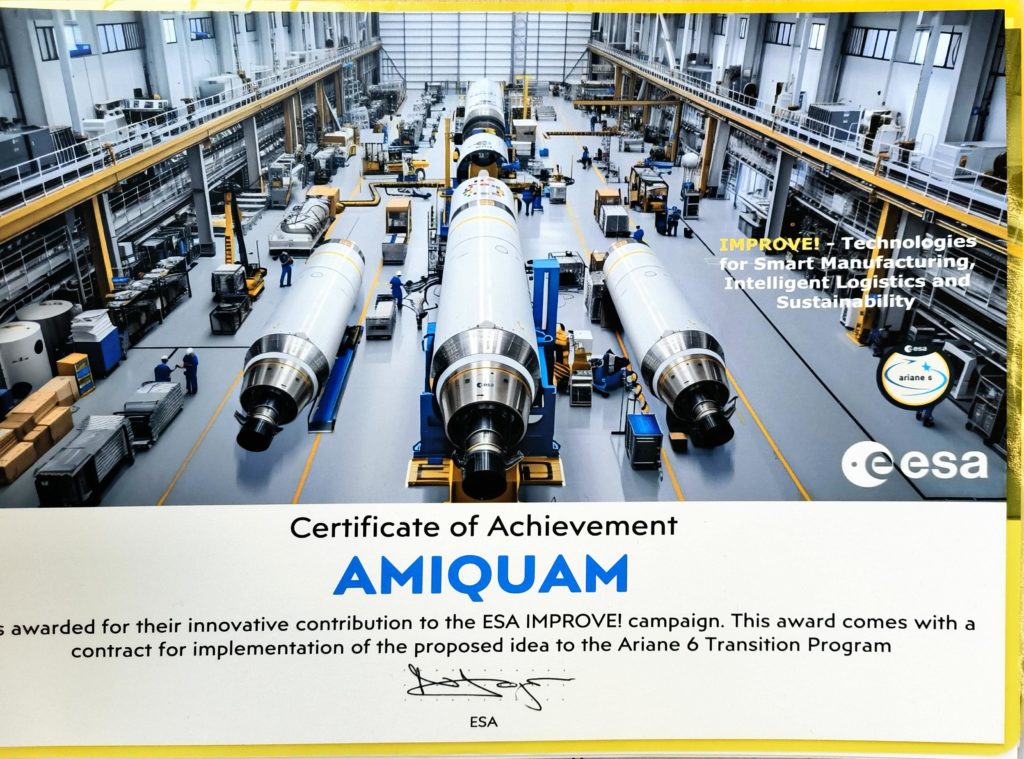

AMiquam awarded by the ESA improve! campaign

We are thrilled to announce that AMiquam has been awarded a prestigious contract with the European Space Agency (ESA) to drive the digitization process in manufacturing as part of the Ariane 6 Transition Program. This remarkable achievement is the culmination of a year-long endeavor to establish AMiquam as a pioneering force in in-situ inspection for…

Read more