Sensors for AM

MONITORS THE QUALITY OF AM PROCESS AND PARTS

Whereas additive manufacturing (AM) gives industry unique design and manufacturing flexibility, the certification of the parts still presents significant challenges. This is the main bottleneck hindering the massive growth of metal AM. Our product and services contribute to solve this issue

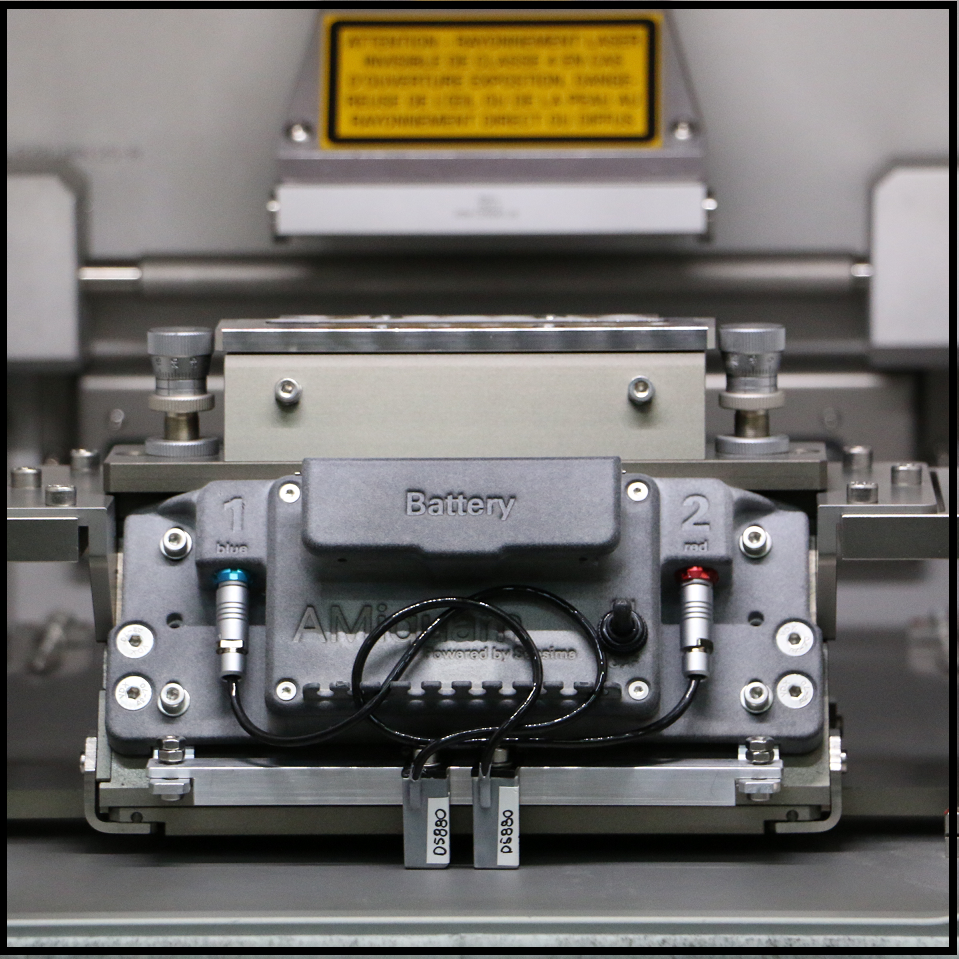

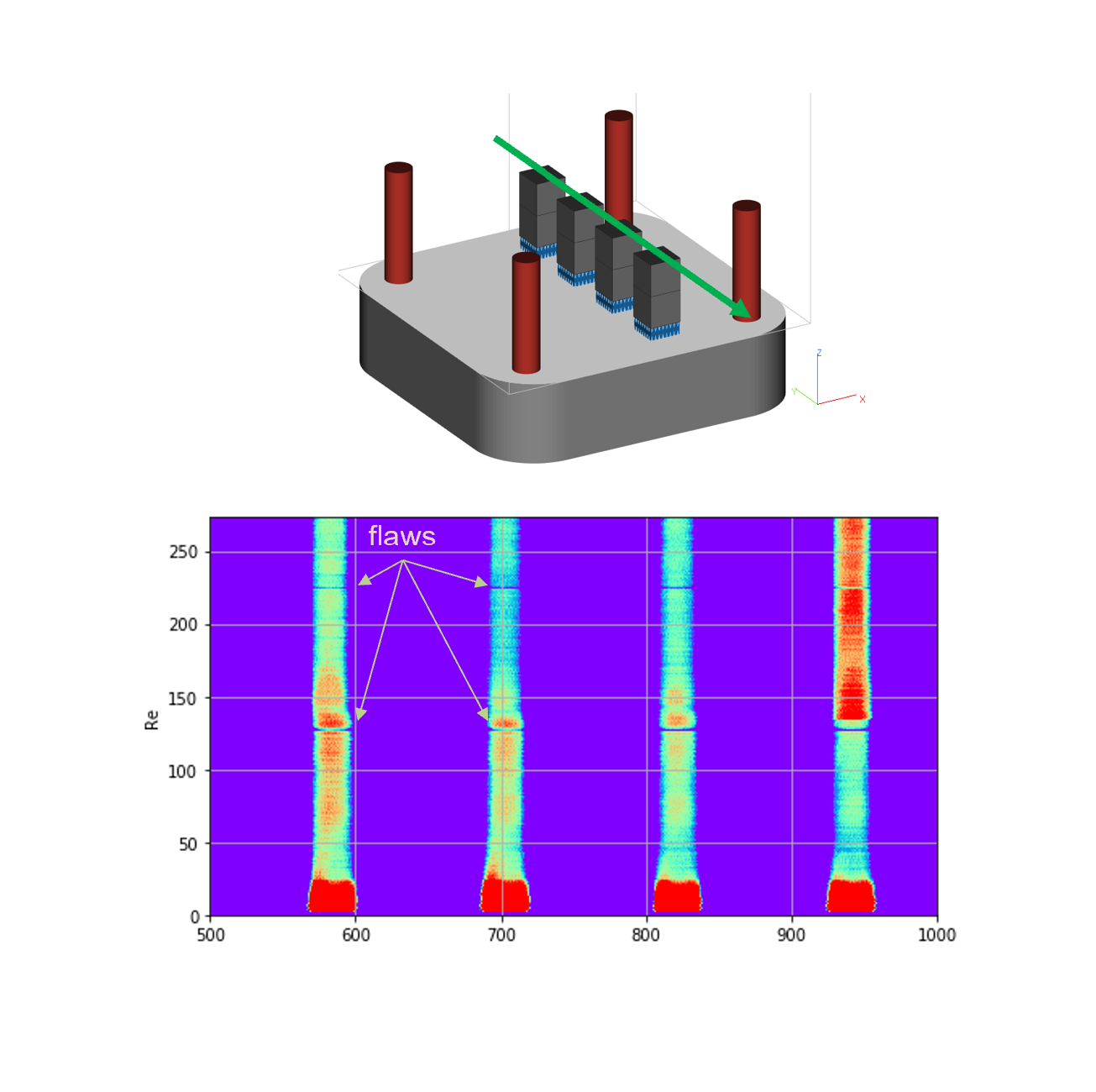

Sensors fixed to the recoater

Process monitoring using NDT compliant sensors

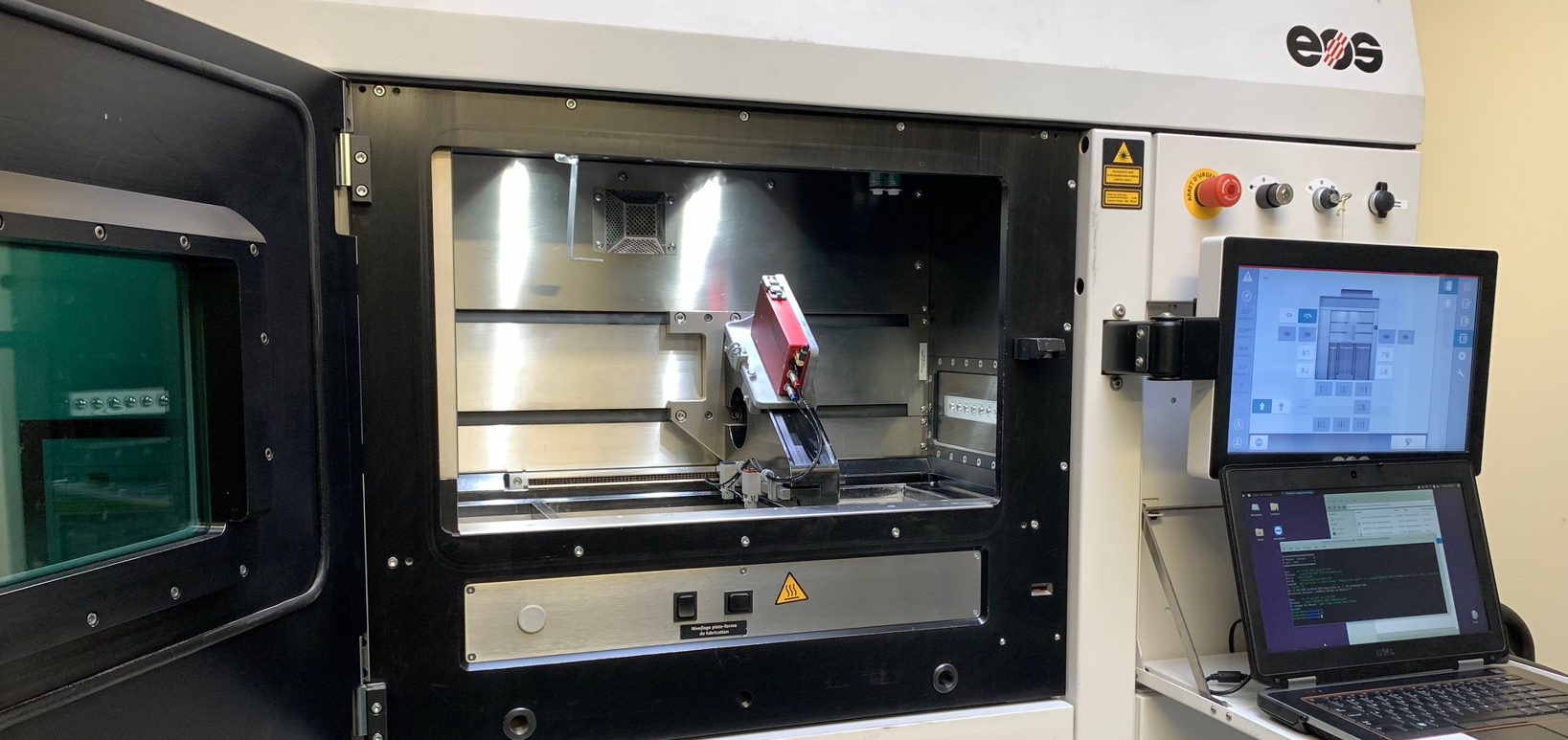

Integration

The module can be integrated in most of the LPBF AM machines. We already instrumented the following machines, ask us if yours is not in the list, we will design the installation kit for you !

- 3DS/GFMS DMP 350

- EOS 290/280

- EOS M300

- SLM Solutions SLM125

- SLM Solutions SLM280

- RENISHAW 400

- RENISHAW 500

- ACONITY LAB, ACONITY MINI

- ACONITY MIDI PLUS

- GE CONCEPT LASER M2

- PRIMA ADDITIVE 250

- TRUMPF TruPrint1000

- ADDITIVE INDUSTRIES MetalFab

- DMG MORI Lasertec 30 Dual SLM

Easy integration in less than 30 minutes

Wireless communication

Acquisition and visualization software

Visualizing quality issues

Differences in material quality are directly detected using our electromagnetic sensors.

These differences can be caused by changes in the process parameters or by localised defects. Early warnings are generated using these data.

GET EARLY WARNINGS AGAINST PROCESS DEVIATIONS

ACCELERATE PARAMETER OPTIMISATION

DETECT POWDER INHOMOGENEITIES AND PARTICLES

PERFORM IN MACHINE METROLOGY

Last News from AMiquam

AMiquam to join the RES2AM consortium

🫕+ 🦌: Proud to be part of RES2AM, a team of excellent AM actors and to collaborate with industry NDT experts from Saab, GKN Aerospace, SKF Group and Ringhals AB on in-situ inspection...

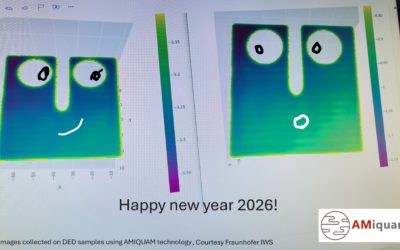

Happy New Year 2026 !

🚀 Closing out 2025 with pride and ambitionAs we wrap up 2025, it’s time to reflect on an incredible hookup year of innovation and collaboration. We are especially proud of our work with ARIANESPACE, European Space Agency – ESA , and several leading aviation...

Full coverage AMIQUAM inspection system installed in a new AMCM/EOS 290 machine

Huge thanks to Christian Seidel for kicking off this groundbreaking project! We’re thrilled to have reached a major milestone: equipping a brand-new machine with a full-coverage eddy current array, a first for us! This achievement wouldn’t have been...