Exploring the response of lattices to eddy currents

It is now well documented that eddy currents can significantly contribute to the QC and NDT of additively manufactured parts, either during the process or in post processing. To fully deploy its potential, the technique has to demonstrate its value for low density structures such as lattices, which are now commonly manufactured with PBF-LB.

We spent two days with our partners from the team of Prof. Fabian Riss (TH Rosenheim), who brought samples that have been measured on our gantry scanner and compared to data collected insitu on their TruPrint machine instrumented with AMiquam technology. Contact us if you are interested in this research.

Lattices structures

Lattice structures are widely used in Additive Manufacturing. They have specific functionalities such as improved thermal management, stiffness, or shock absorption. Lattices are particularly useful in the aerospace, automotive, and medical sectors where material efficiency and performance customization are crucial.

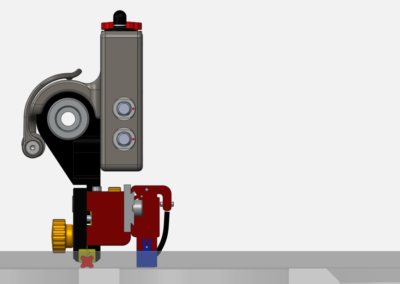

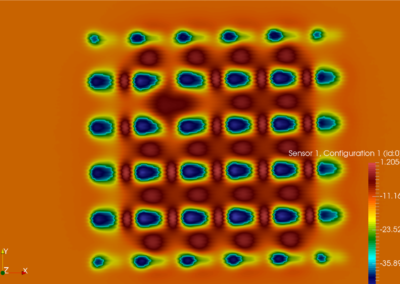

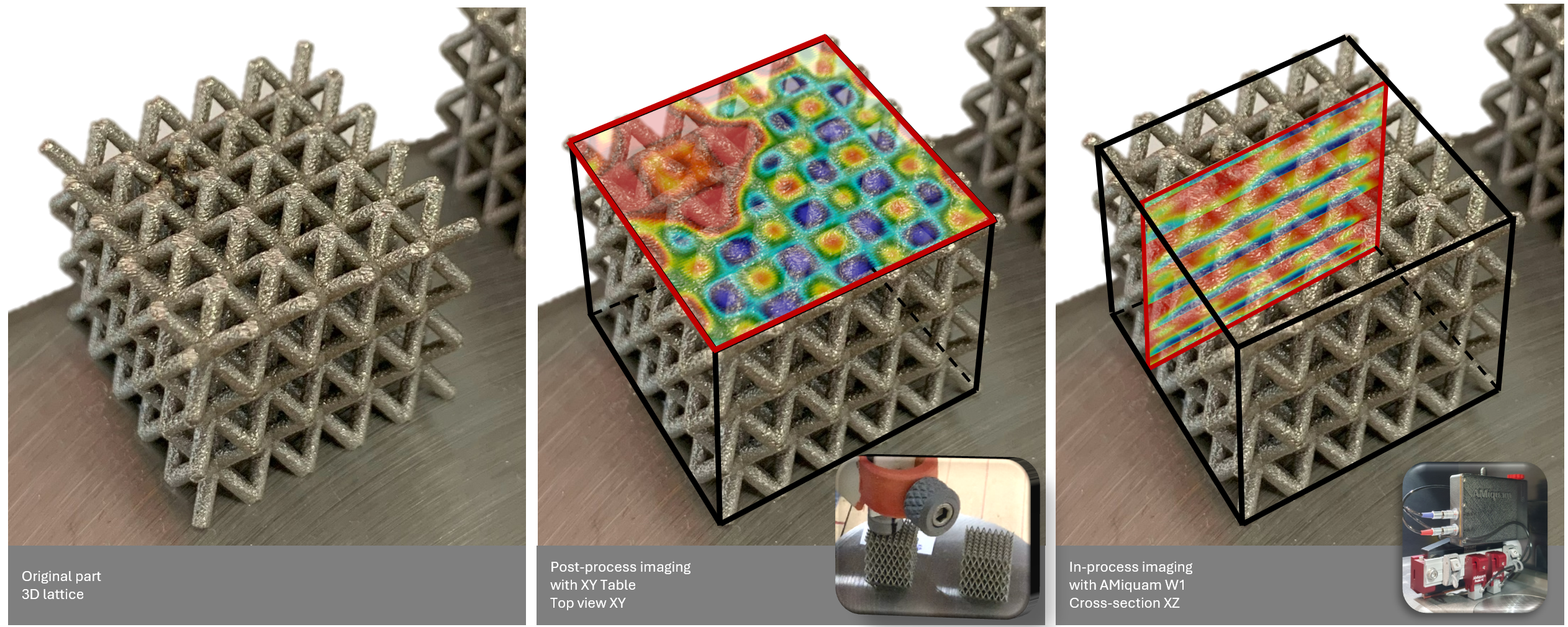

AMiquam W1 module, a compliant NDT method using Eddy Current technology scans the lattice during the fabrication and produces XZ images that correspond to the plane of the recoater motion (X) and the layer height (Z).

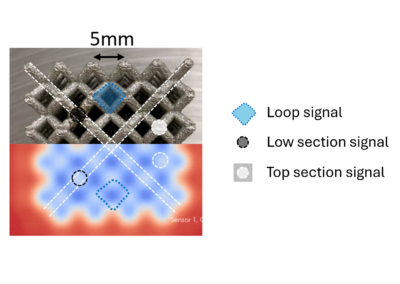

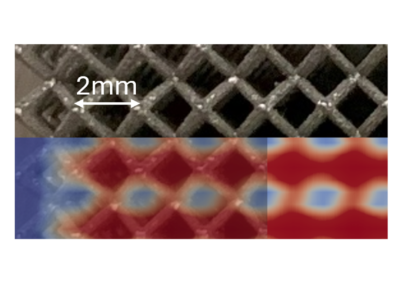

The image above illustrates the cross-section images acquired by the Eddy Current systems. The same probe is used and the same parameters are applied for the two different scans. The middle image is a top-view XY raster scan recorded after the fabrication with the high precision gantry table. The right images is a typical insitu XZ scan recorded during the lattice print in the Trumpf TruPrint 1000.

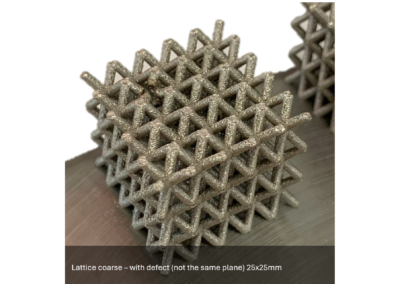

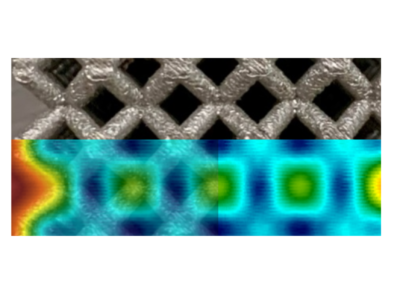

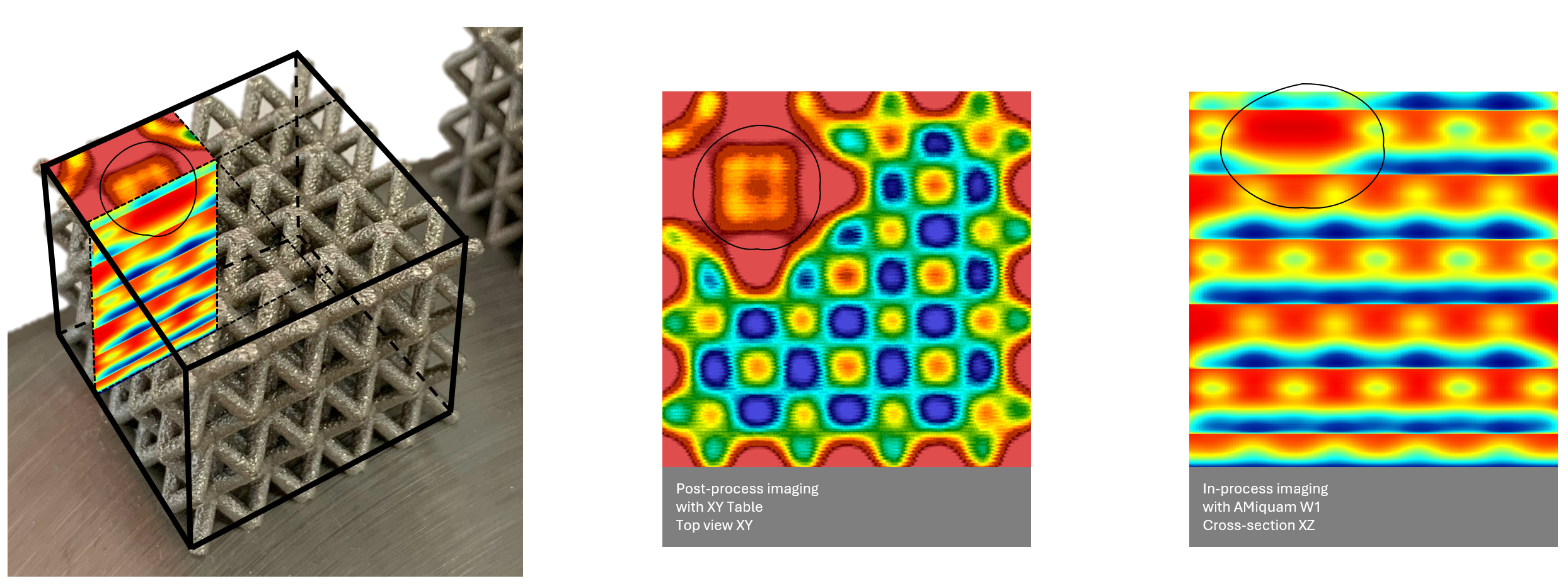

A defect in the lattice will likely result in a modification of Eddy Current electromagnetic signals. The image below represents a lattice with a defect (non-connecting unit cell). The defect is visible with the top-viewand the insitu images.

Illustrations

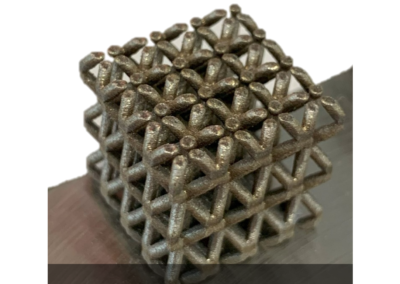

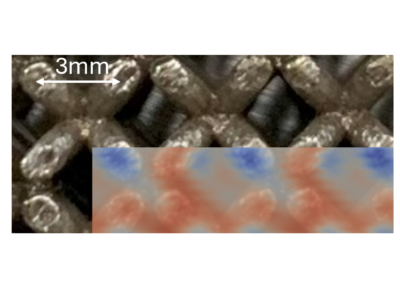

The gallery illustrates the AMiquam module W1 installed in the TruPrint 1000, the printed parts and some results of the scans.