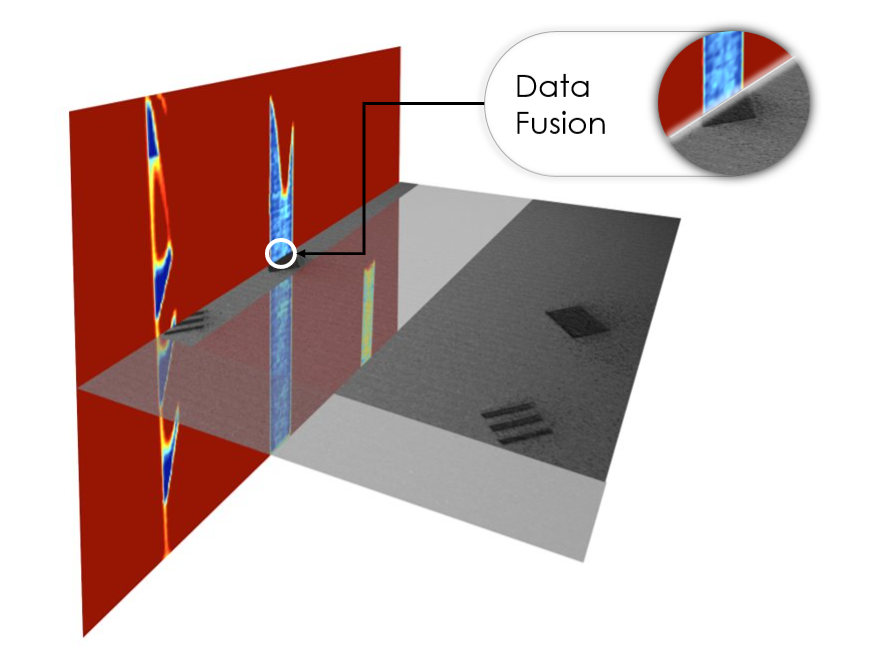

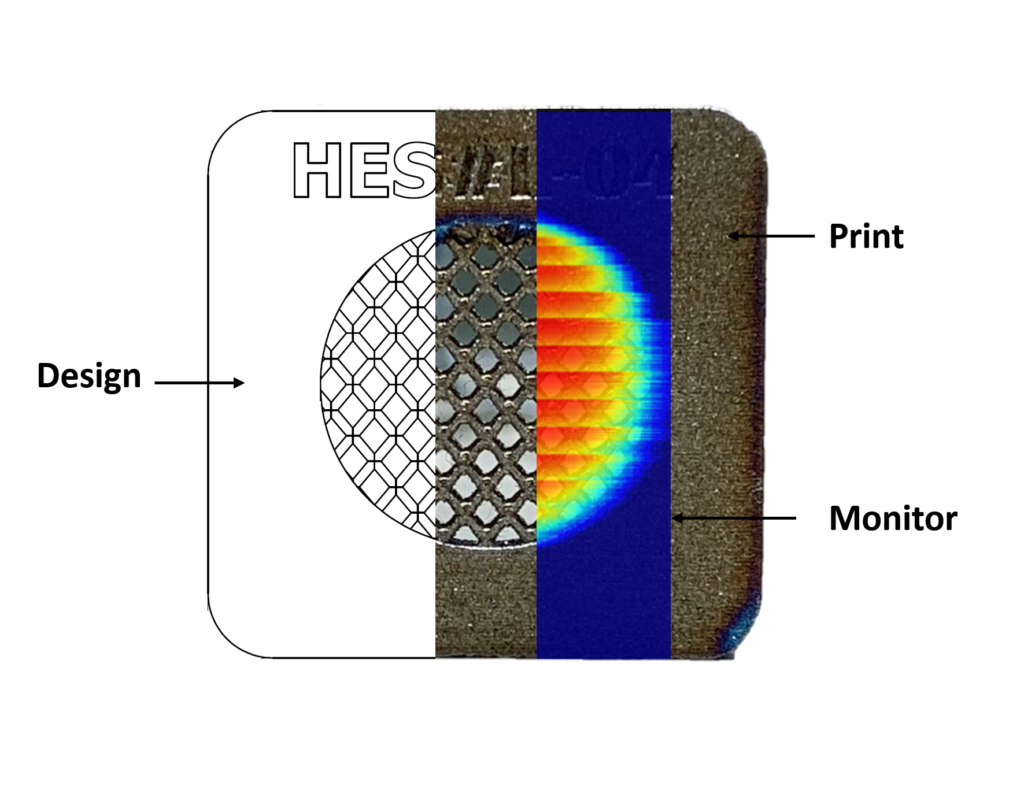

Data Fusion – Eddy Current and Camera images

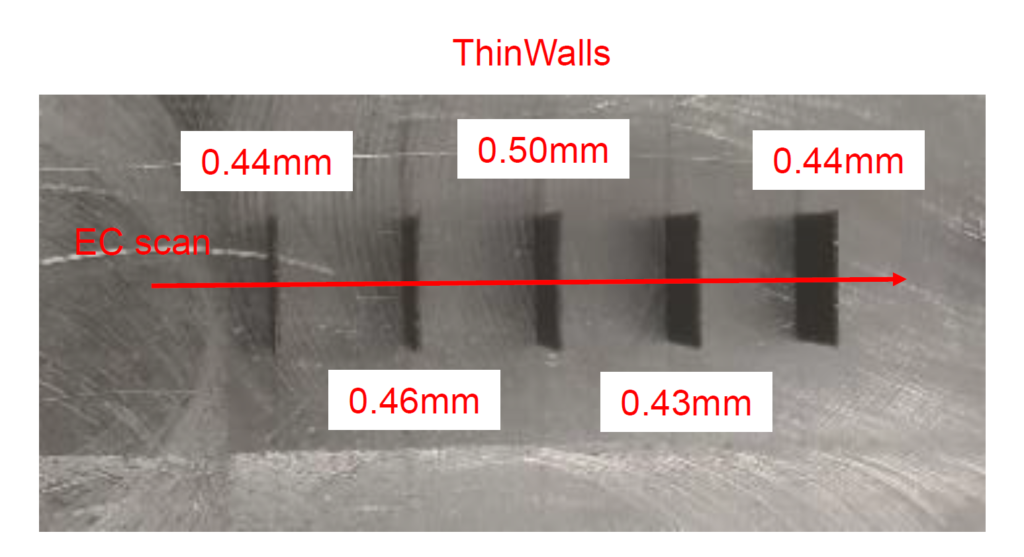

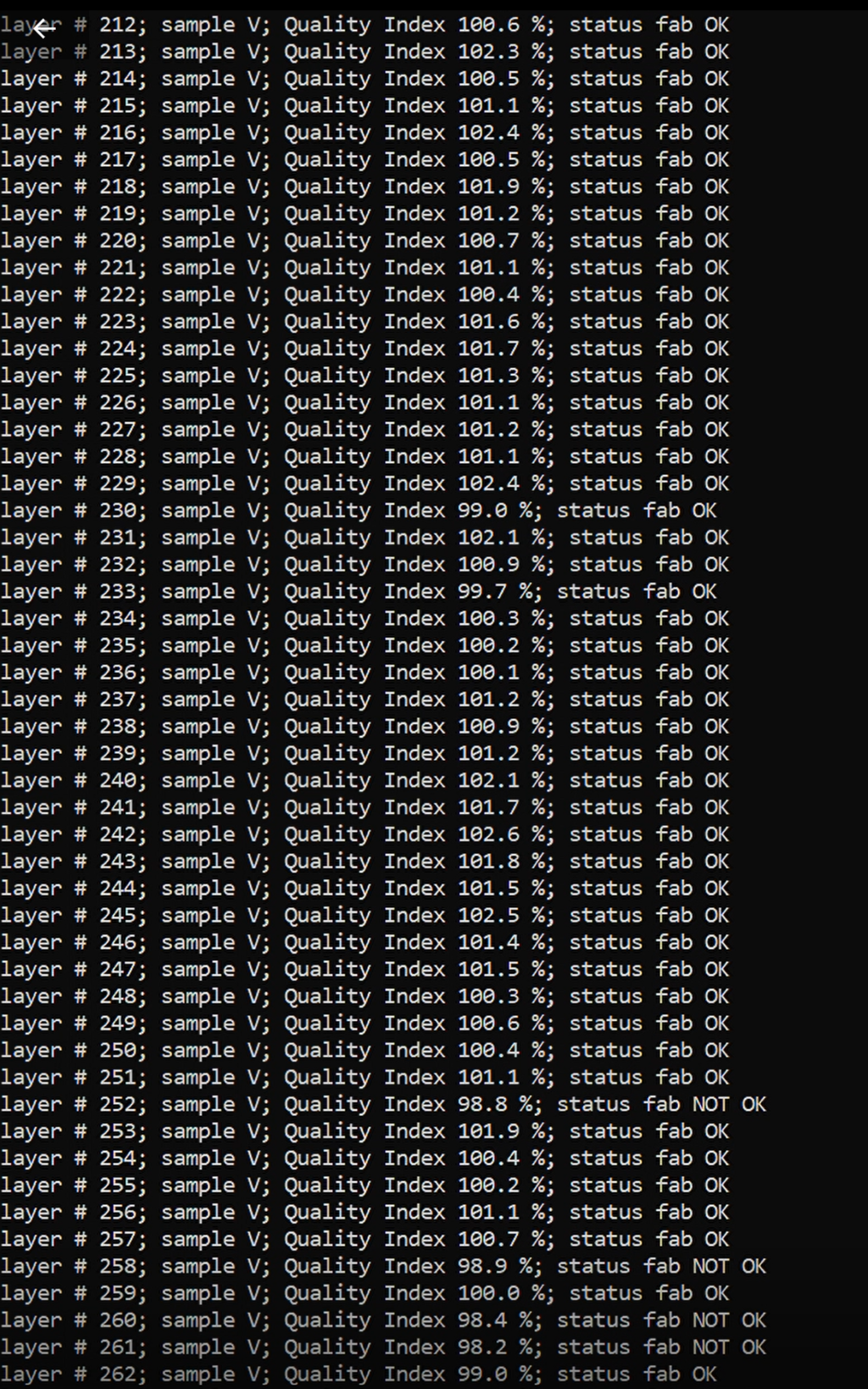

AMiquam releases a new Data Fusion solution for metal AM, merging AMiquam electromagnetic imaging and off-axis optical imaging (present in every machine). Combining ground truth and coverage, a new dimension for quality management of the metal AM process. Ready to create machine learning data sets for AI with your data, improving compliance and simplifying qualification. Many thanks to our partner Eric Baustert from Volum-e for letting us share the data.