Exploring the response of lattices to eddy currents

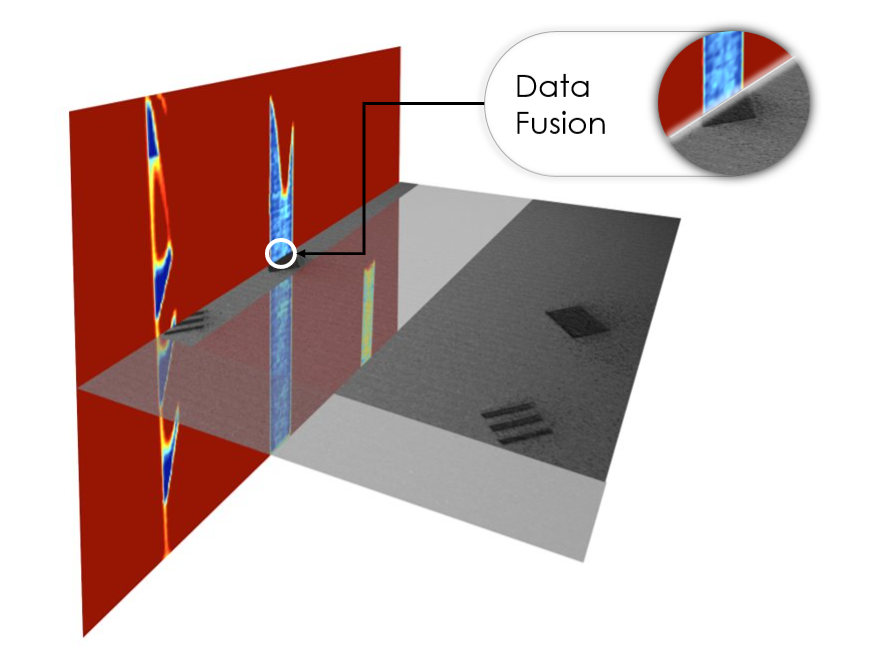

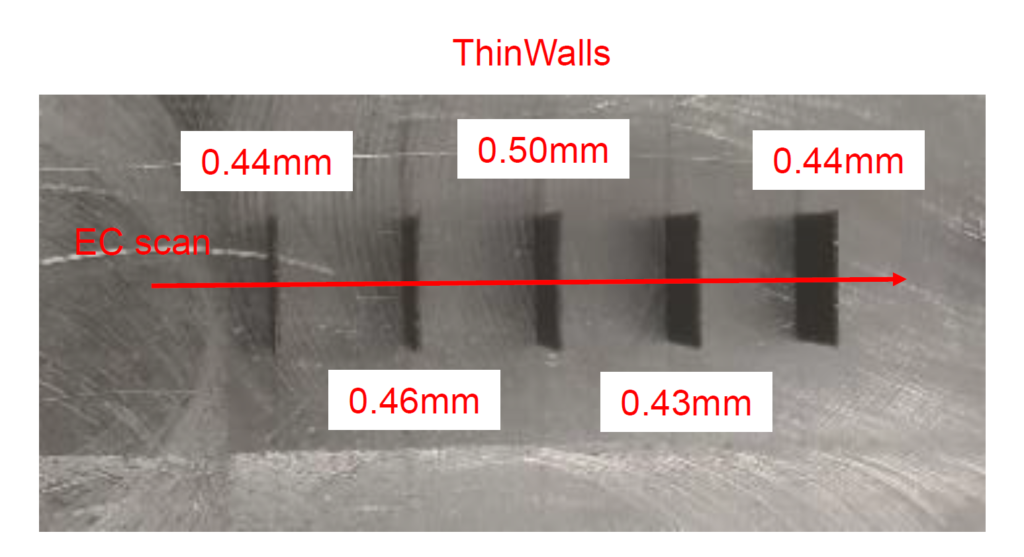

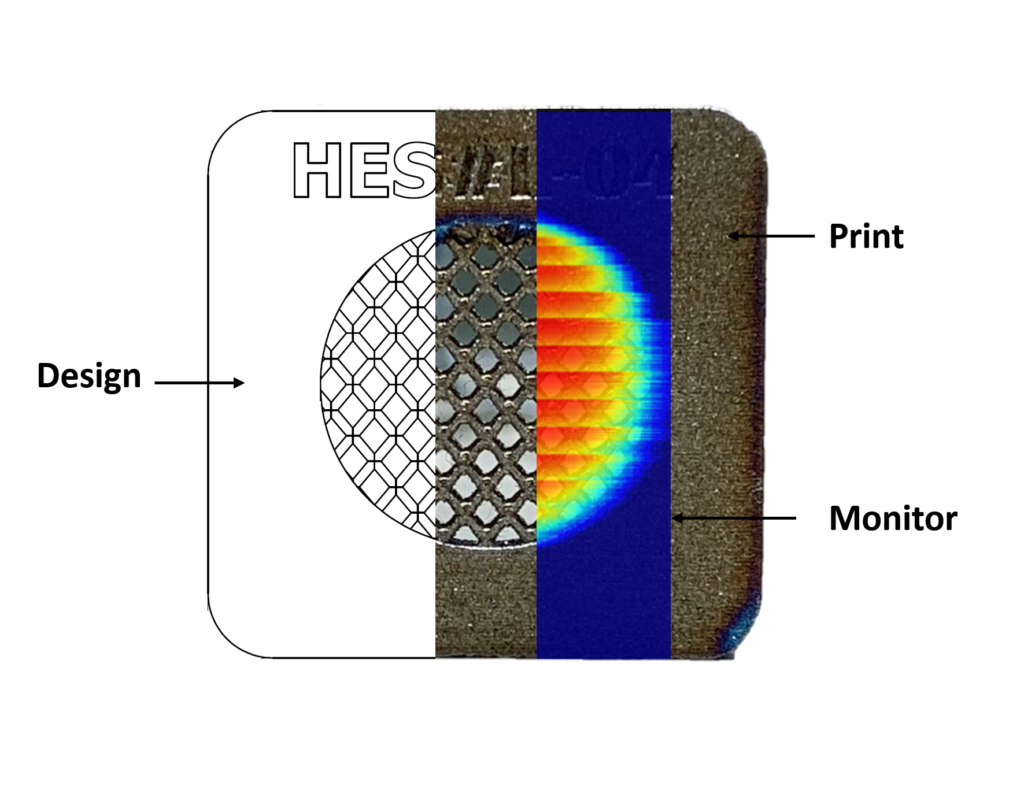

It is now well documented that eddy currents can significantly contribute to the QC and NDT of additively manufactured parts, either during the process or in post processing. To fully deploy its potential, the technique has to demonstrate its value for low density structures such as lattices, which are now commonly manufactured with PBF-LB.