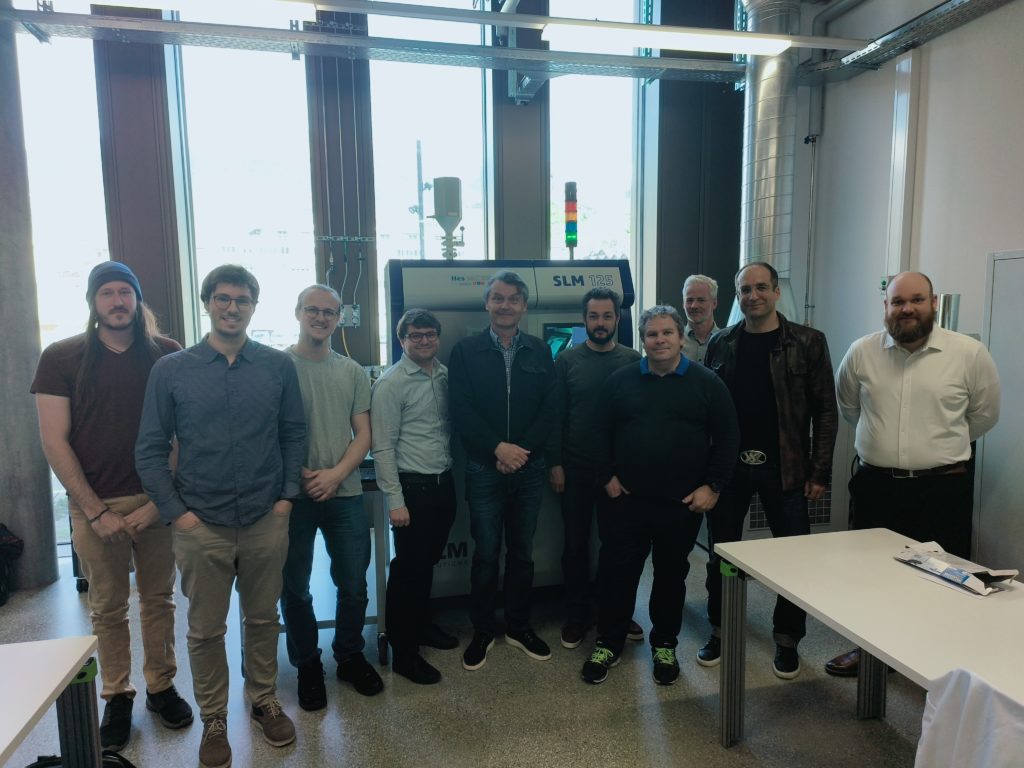

FieldMade visit to AMiquam

Had a great meeting yesterday discussing the future of quality control and monitoring in metal additive manufacturing with our colleagues from Fieldmade AS, armasuisse Wissenschaft und Technologie, and HES-SO Valais-Wallis. The AMiquam team presented a new design of the in situ NDT/monitoring system installed in a Nikon SLM Solutions machine. Based on this design, the…

Read more