Happy New Year 2026 !

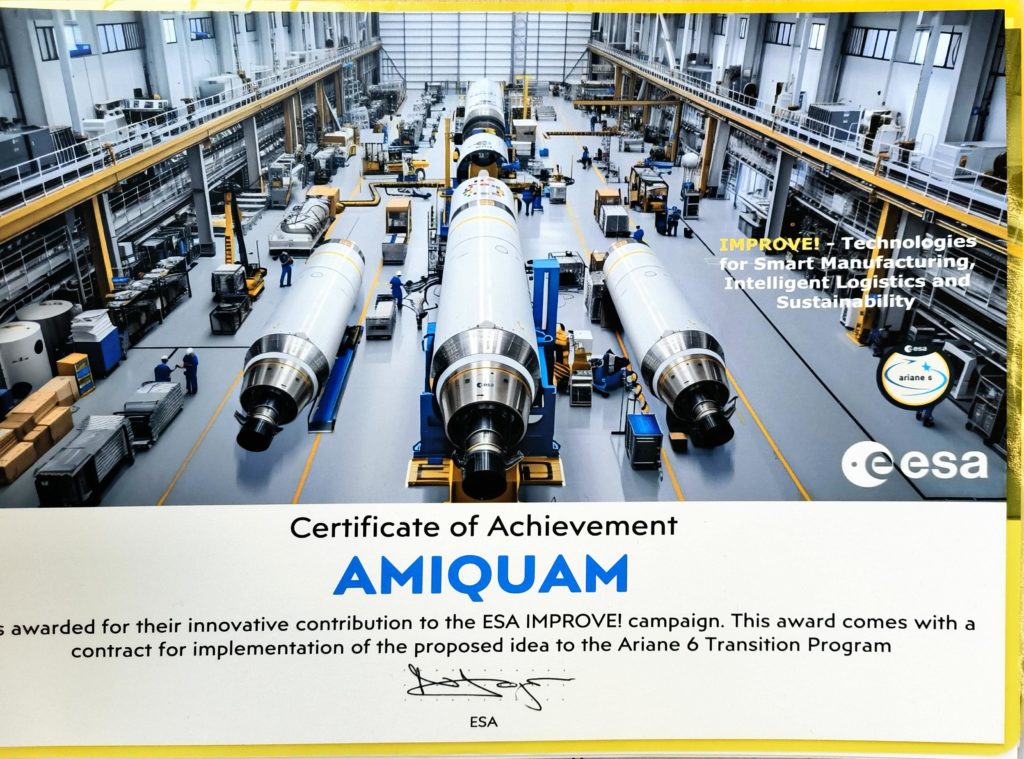

🚀 Closing out 2025 with pride and ambition As we wrap up 2025, it’s time to reflect on an incredible hookup year of innovation and collaboration. We are especially proud of our work with ARIANESPACE, European Space Agency – ESA , and several leading aviation parts manufacturers. ✈️ Aviation regulatory boards like Federal Aviation Administration…

Read more