Process variations and small defect detection

The industry is pushing us to demonstrate our capability to detect tiny defects in the 0.1mm range using our in-situ inspection technology. Fortunately, we’re making progress towards achieving this goal, as evidenced by the above data collected during a fabrication process instrumented with our AMiquam product in the laboratory of our partner, Professor Fabian Riss, at TH Rosenheim. This data reveals that defects as small as 0.2mm can be readily visualized and automatically detected without requiring sophisticated data processing techniques. However, the smaller 0.1mm seeded defects are not apparent in the data, although we cannot conclusively determine whether they are actually present in the sample or not. This highlights two key challenges hindering the validation of our system by the customer: firstly, the complexity of intentionally introducing defects within the 0.1mm range into the sample, and secondly, the considerable time required to verify the existence of such defects through post-processing methods, while our data is available in real time.

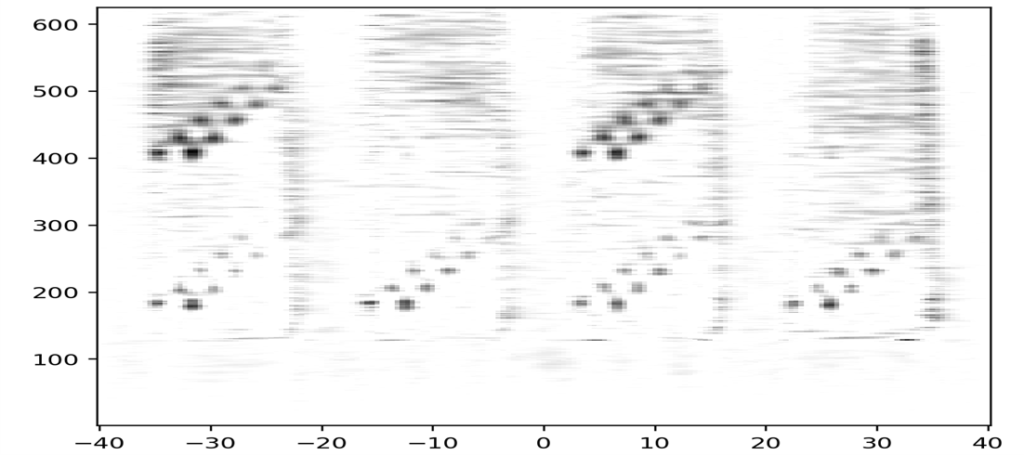

As we work to replicate these results across different machines and locations, we’ve encountered a challenging issue: the process variations that cause layer-by-layer variations of the material properties. These appear as horizontal black lines in the image above, which need to be distinguished from the defect-induced double peak, and can be substantial and may prevent the manufacturing of small features and/or mask their faint signal.

Currently, we lack a clear understanding of the underlying causes of this phenomenon, which likely relates to the interaction between the laser and the plasma plume with the influence of the gas flow properties. To better quantify this effect and determine its impact on the sensitivity of our product to small defects, we’ve developed a metrics to measure process fluctuations using the physical properties of the material measured with our electromagnetic system.

While it’s possible to mitigate these variations through post-processing, wouldn’t it be preferable to have a machine that inherently exhibits minimal fluctuations, eliminating the need for additional processing heat treatment and associated costs and delays ? We’ve identified specific machine features that reduce these fluctuations and have established a test protocol to quantify them. Before purchasing your next machine, why not consult with us to ensure you’re getting the best possible performance, both for the homogeneity of your parts and for the capability of insitu inspection to detect small defects and provide in situ part certification ?