Technology at a glance

AMiquam Technology inherits of a know-how of more than 10 yeas in Eddy current Non Desctructive Testing.

EDDY CURRENT SENSOR

EC testing is one of several non-destructive testing methods that use the electromagnetism principle for flaw detection in conductive materials. A specially designed coil energized generates a changing magnetic field that interacts with the test-part and produces ECs in the vicinity.

WIRELESS MODULE

The AMiquam wireless module uses the bluetooth technology to transfer the insitu sensor data outsite the machine. The module does not require wired power supply. The great advantage is the simplicity to install the module and to acquire the data.

ELECTROMAGNETISM

The sensor performs electrical conductivity measurements as described in the norm ASTM 1004, to monitor the stability of the AM process. The technique is differentiating in the sense that it probes the AM material up to a depth of about 0.5mm contrarily to other monitoring equipments.

Z-AXIS MEASUREMENT

The height between the fabricated parts and the probe is measured at each layer. The inductive sensors are known for their precision, insensitivity to contamination, since contactless and their low wear. They are largely used in automation such as electronical and mechanical industries.

AMIview software

Inspect the parts and calculate the statistics on each region of your fabrication.

– Load fabrication file and calibration files

– Explore the electromagnetic sensors data

– Select regions of interest and calculate statistics

– Export the data in pictures format, tables or graphs

Designed by rawpixel.com

Contact us! We will arrange a visio-meeting #covid19

Insitu NDT measurement

Have you have dreamed to perform a direct electromagnetic measurement inside the machine during your fabrication without alteration of the printed part ? AMiquam wireless did it !

Fixed to the recoater, the sensor scans multiple lines. The “non desctructive testing” produces a XZ-scan with a single probe. The more probes you have, the more 3D you are !

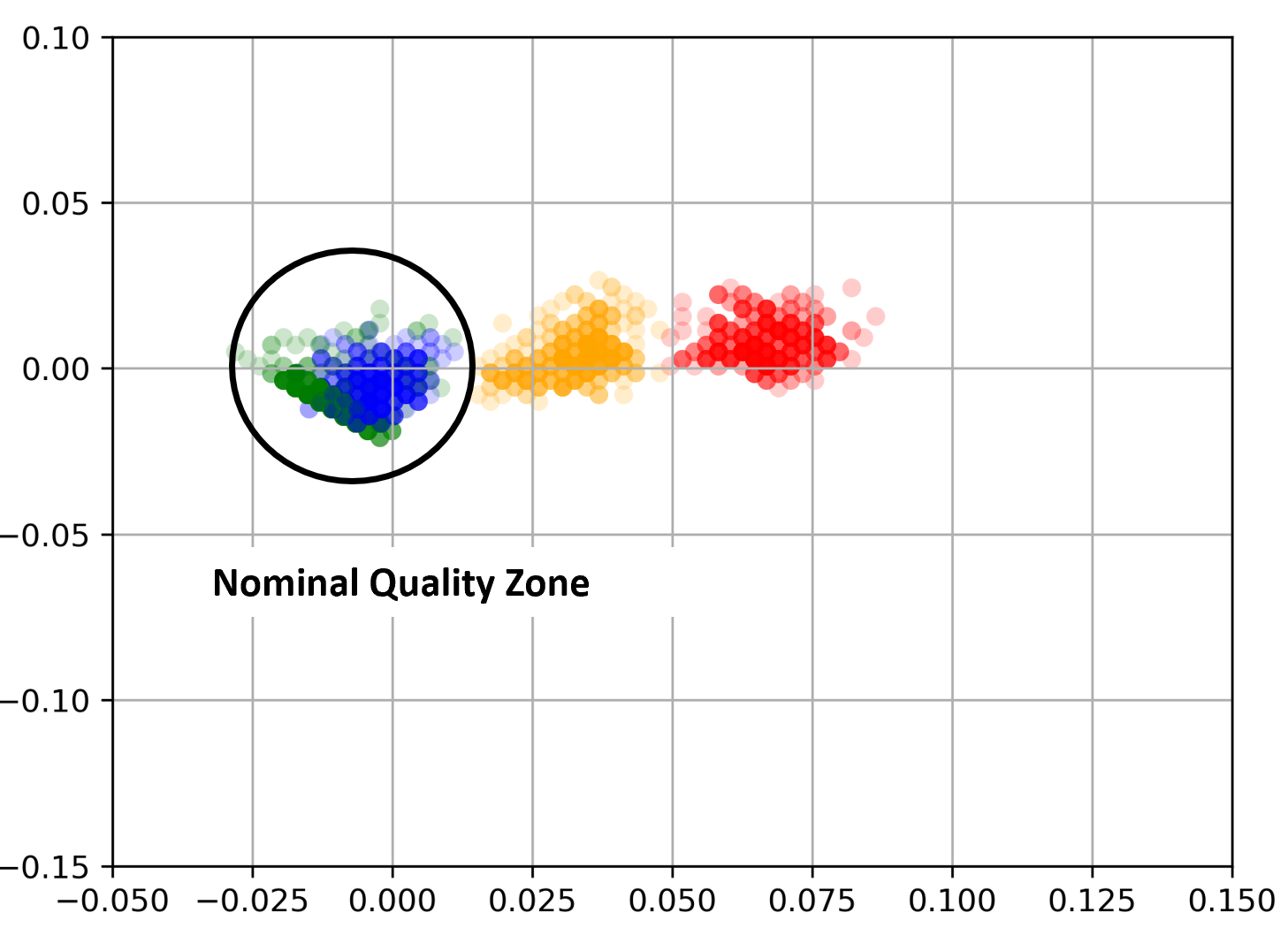

Each sample is represented in a specific region of the plane. At each layer, a new information appears !

4 samples with different parameters. Blue and green values are the Nominal Quality Zone.

Performance

Our ambitious objective :

Monitor every parts of the Additive Manufacturing industry.

Be the next to monitor your parts

z-axis resolution

Data Transfer Rate

layers under the probe

We are proudly supported by